Ascension 1938; the tiny 9 1/2 mile (13,7km) long island in the mid-Atlantic has become a centre of international trade and a stopover for airships carrying the rich and famous, the unscrupulous and the downright criminal.

Amongst the latter are the oddly named 40 Elephants Gang (link) , a largely female gang of thieves who started shoplifting in fashionable parts of London, but are branching out into other areas. They have been contracted to steal a package allegedly containing a mysterious “Jewelled Tome” being kept in the Montaro Warehouse and due for transport today.

Captain Bryant of the Royal Naval Air Service police, which is the only police force on the Island, has been tipped off and his small squad are rushing to stop the heist…

The 40 Elephants have moved in just as the Jewelled Tome was loaded into the van. The crew have escaped and had the presence of mind to lock the door on the way.

Getting into the van takes some time. Above Jim Bullock, the Leaders Sidekick and the main muscle, is trying to smash a window on the left, while Shirlie Pitts is using her cunning to pick the lock.

Meanwhile gang leader Alice Diamond (L) and follower Florrie Holmes (R) use their combined finesse to remove a fuse from a power switch, so no-one can raise the alarm…

Fortunately Capt. Bryant and the RNAS police are already near the scene. Bryant and Lt. Cain get into the car while Sgt Williams and Sgt. Coulson scout out the alleyways.

Immediately Williams spots “Matron Fox” of the Auxiliary police, and a local character known as “Lev the Anarchist”, lurking around several crates marked “Explosives”. He moves in to investigate and Fox, unwisely under the circumstances, takes a shot at him while hiding behind the crates. His returning shot predictably hits the boxes of TNT which go bang, whereupon she loses any further interest in the affair. ‘Lev’, is unscathed, apparently immune to explosives.

Meanwhile, Capt. Bryant and Lt. Cain are racing through the narrow streets in the police car.

Fortunately for the Police, Shirlie and Jim appear to be working at cross purposes. As Shirlie later explained “I woz tryin’ to open the door, and every time oi got moi skeleton key in der lock, Jim would ‘it the van on the ovver side so it’d fell out again, and then I’d try again and ee’d ‘it it again.” Eventually however Jim “Jemmied it good” allowing them both access to the vehicle.

They roared out of the yard, and…

Meanwhile, it turns out the explosives were a consignment the Auxiliaries were intending to sell to the 40E Gang, presumably to open the van later. Diamond and Holmes approached but hearing gunshots narrowly avoided a confrontation.

The van itself, driven by Jim, is trying to escape the police. Jim turns wildly down an alleyway…

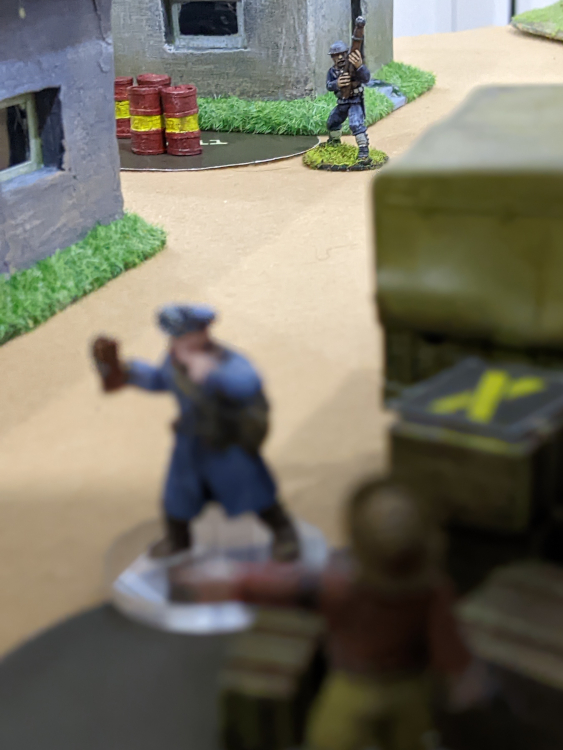

…with the police in hot pursuit. The other member of the 40e Gang, Mary Carr, can be seen in the distance, Not to be outdone she fires a volley at the police car but fails to cause serious damage.

However, all is not well for Jim in the van. in turning down the alley he hits an oil slick and loses control (The random peril was finesse, which Bullock isn’t good at); the van careens forward, smashes into a wall, narrowly missing Diamond, and slams into the building opposite. Being a security van this doesn’t do a lot of damage, but it does stop them.

The police are in a difficult position now; if they go forward they risk hitting the same oil slick and crashing themselves. Bryant opts to block the escape and let the rest of the squad move in.

Williams gets to the van first but is foiled by Diamond. He’s focused on Jim Bullock in the van, makes the mistake of ignoring the petite blonde and regrets it when bullets start zinging around his helmet.

While Diamond distracts Williams, Bullock has managed to reverse the van, The road behind is blocked but he manages to change gear and races off up the road; the chase is on; again.

Jim Bullock and Shirlie Pitts race off in the truck, with the “Jewelled Tome” still in the back. Bryant sets off in Pursuit, passing the random peril for the control check and incidentally somehow passing Alice Diamond unscathed, despite her firing a full revolver at him from point blank range.

As this was turn 6 the 40 Elephants had “Won,” making this a successful début on the island, but the RNAS police won’t be far behind; they can’t be on an Island less than ten miles long…

While all this was happening, Florrie Holmes had slipped off to a quieter corner, and found a box of what looks suspiciously like hooch, which she then purloined on General principles. As Ascension has become a regular dropping off point for Mafia deliveries of booze to the US, this may come back to bite her at a later date…